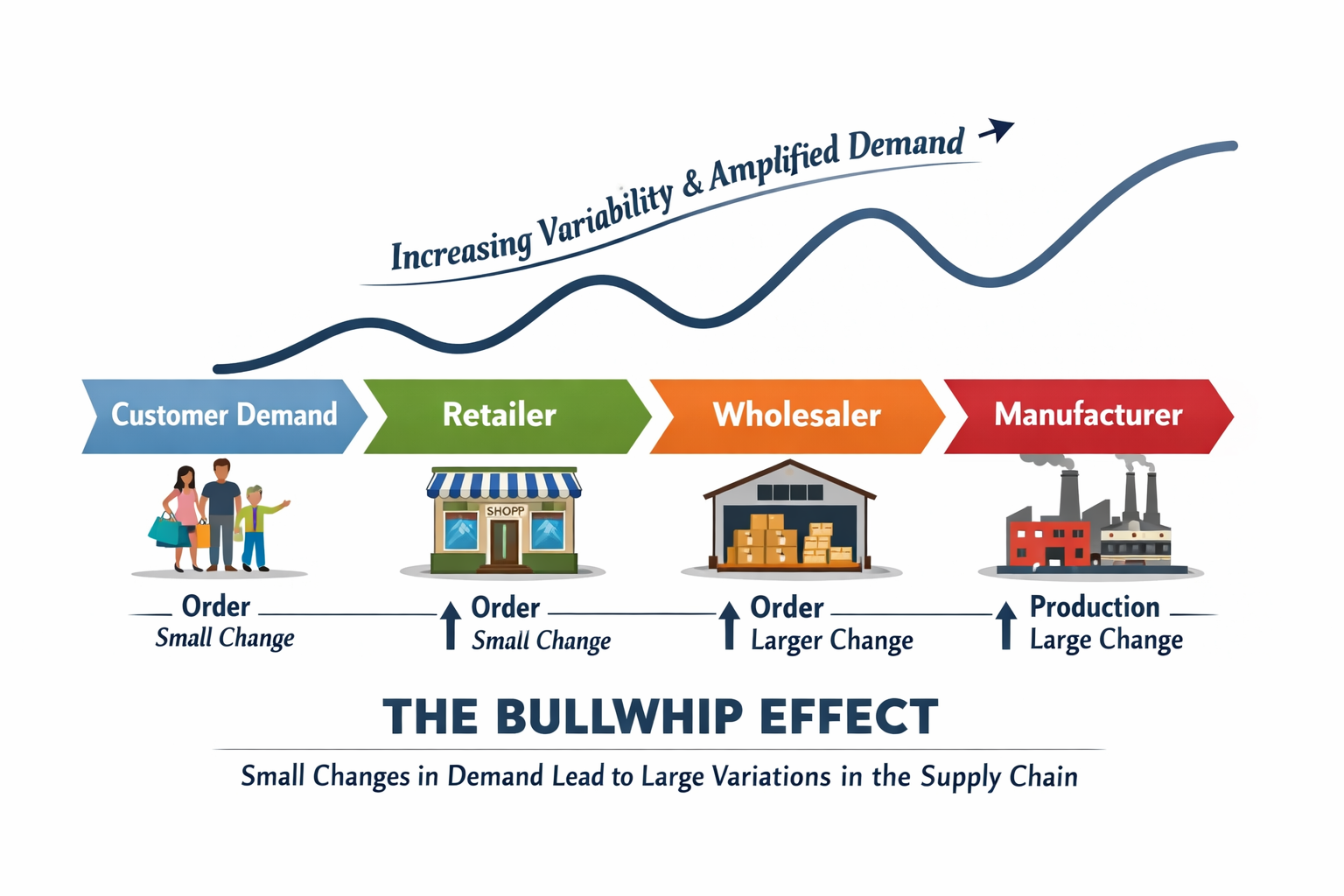

Small Changes Create Big Shifts

Supply chains are complex, interconnected systems where small fluctuations can amplify dramatically—known as the bullwhip effect, where minor demand changes at retail cause massive upstream swings in orders and inventory. Conversely, targeted small improvements in visibility, forecasting, or collaboration can dampen this variability, yielding outsized gains in efficiency, cost savings, and resilience.

The Amplification Principle in Action

The bullwhip effect illustrates negative amplification: A 5-10% retail demand shift can balloon to 40-50% variability at manufacturers, leading to excess inventory, stockouts, and higher costs. In 2025-2026 trends, better demand forecasting via AI reduced this effect, turning small accuracy gains (e.g., 10-15% better predictions) into 20-30% lower inventory holding costs.

Real-world examples abound:

Information sharing and unified platforms → One company improved inventory turns by over 200% and cut supply chain spend in half by reducing silos.

AI-enhanced forecasting → In 2025 logistics, integrating external signals smoothed variability, enabling 15-25% inventory reductions.

Minor process tweaks → Optimized warehouse picking or pallet transport unlocked scalability and safety gains, flattening peak labor demands.

Why Small Changes Yield Big Results

Incremental steps—like real-time data sharing, API integrations over legacy EDI, or modest reskilling—compound across multi-tier networks. Reducing lead time variability by 10% can cut bullwhip-induced costs by 20-40%, while slight forecasting improvements lower excess stock dramatically in long chains.

In 2026, as automation refines and AI embeds deeper, these "small" levers—better visibility, collaborative planning, dynamic routing—will drive resilience amid tariffs, labor shifts, and volatility. Leaders focusing on marginal gains today will see exponential stability and profitability tomorrow. The whip cracks both ways: Dampen the negative swings, and positive changes amplify.